A thermoelectric material that can be used in wearable devices such as smart clothing and maintains stable thermal energy performance even in extreme environments has been developed by a team of Korean researchers. It has dramatically resolved the dilemma of striking the balance between achieving good performance and the mechanical flexibility of thermoelectric materials, which has been a long-standing challenge in the field of thermoelectric materials, and has also proven the possibility of commercialization.

The joint research team of Professor Yeon Sik Jung of the Department of Materials Science and Engineering and Professor Inkyu Park of the Department of Mechanical Engineering, in collaboration with the research teams of Professor Min-Wook Oh of Hanbat National University and Dr. Jun-Ho Jeong of the Korea Institute of Machinery and Materials, has successfully developed bismuth telluride (Bi2Te3) thermoelectric fibers, an innovative energy harvesting solution for next-generation flexible electronic devices.

The work is published in the journal Advanced Materials.

Thermoelectric materials are materials that generate voltage when there is a temperature difference and convert thermal energy into electrical energy. Currently, about 70% of energy being lost is wasted heat, so attention is being given to research on sustainable energy materials that can recover and harvest energy from this waste heat.

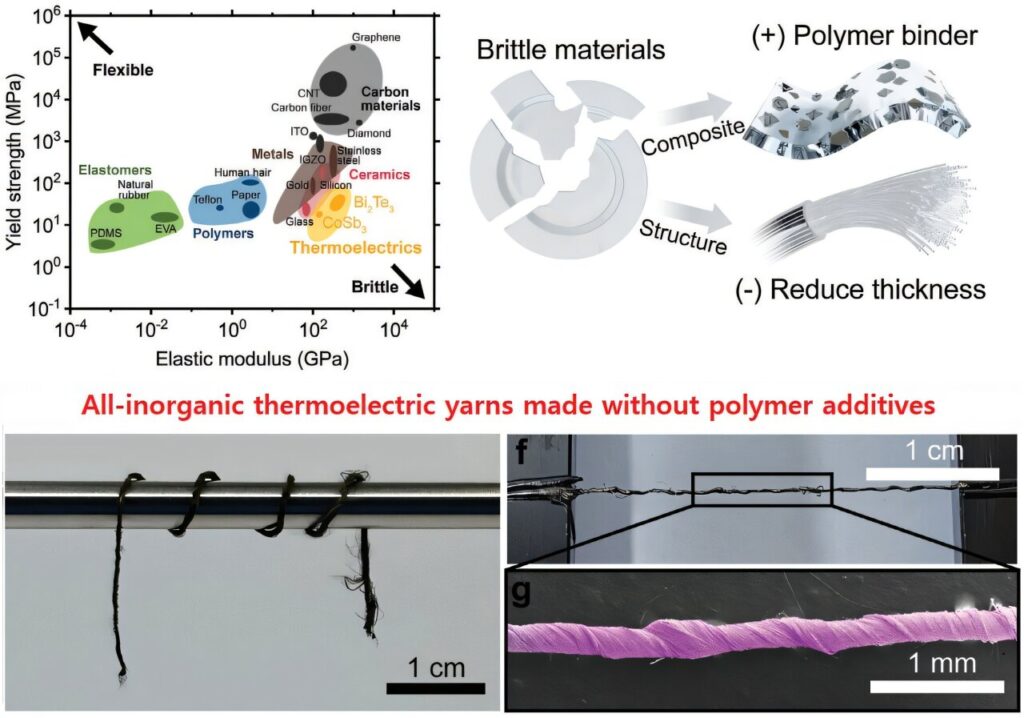

Most of the heat sources around us are curved, such as the human body, vehicle exhaust pipes, and cooling fins. Inorganic thermoelectric materials based on ceramic materials boast high thermoelectric performance, but they are fragile and difficult to produce in curved shapes. Meanwhile, flexible thermoelectric materials using existing polymer binders can be applied to surfaces of various shapes, but their performance has been limited due to the low electrical conductivity and high thermal resistance of the polymer.

Existing flexible thermoelectric materials contain polymer additives, but the inorganic thermoelectric material developed by the research team is not flexible, so they overcame these limitations by twisting nano ribbons instead of additives to produce a thread-shaped thermoelectric material.

Inspired by the flexibility of inorganic nano ribbons, the research team used a nanomold-based electron beam deposition technique to continuously deposit nano ribbons and then twisted them into a thread shape to create bismuth telluride (Bi2Te3) inorganic thermoelectric fibers.

These inorganic thermoelectric fibers have higher bending strength than existing thermoelectric materials, and showed almost no change in electrical properties even after repeated bending and tensile tests of more than 1,000 times. The thermoelectric device created by the research team generates electricity using temperature differences, and if clothes are made with fiber-type thermoelectric devices, electricity can be generated from body temperature to operate other electronic devices.

In fact, the possibility of commercialization was proven through a demonstration of collecting energy by embedding thermoelectric fibers in life jackets or clothing. In addition, it opened up the possibility of building a high-efficiency energy harvesting system that recycles waste heat by utilizing the temperature difference between the hot fluid inside a pipe and the cold air outside in industrial settings.

Professor Yeon Sik Jung said, “The inorganic flexible thermoelectric material developed in this study can be used in wearable devices such as smart clothing, and it can maintain stable performance even in extreme environments, so it has a high possibility of being commercialized through additional research in the future.”

Professor Inkyu Park added, “This technology will become the core of next-generation energy harvesting technology, and it is expected to play an important role in various fields from waste heat utilization in industrial sites to personal wearable self-power generation devices.”