Food safety and security are global concerns as food can easily be spoiled by various pathogens and chemical contaminants, causing fatal diseases in consumers. Ensuring a steady and healthy food supply requires improving food handling, distribution, storage, and quality measures.1

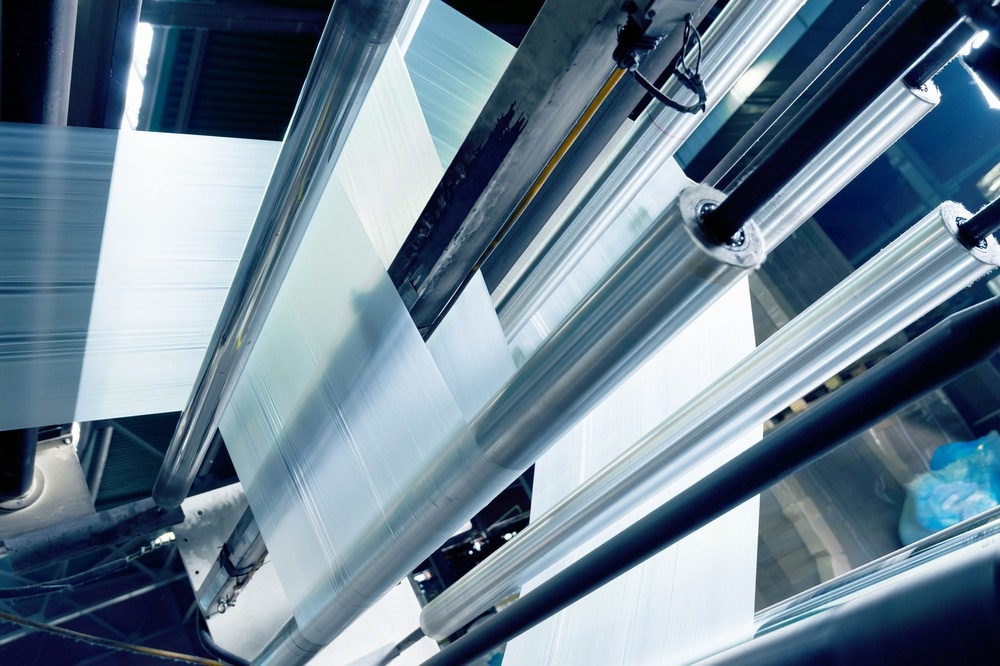

Image Credit: Shutterstock.com

Nanotechnology has found applications in several technical fields, including food technology. Nanomaterials modified into different forms like nanotubes, nanosheets, and nanofibers exhibit attractive physical, chemical, and biological activities. These attributes have led to the development of nanocoatings to protect food from microbial and chemical contamination.2

This article explores the properties of nanocoatings and their potential to improve food safety.

Properties and Benefits of Nanocoatings

Traditionally, antimicrobial additives, thermal treatments, cold storage, and drying techniques are employed to ensure food safety. However, these methods have limitations, including damage to food ingredients due to heat treatment, harm to human health from chemical additives, and the development of antibiotic-resistant food-borne pathogens.3

Nanocoatings offer an alternative, preserving food’s sensory properties (firmness, color, and texture) and nutritional content. They have a larger contact area with the food surface than micro/macro-sized materials, helping delay spoilage and increase the shelf life of food.3

Nanocoatings can be optimized to exhibit antibacterial properties, preventing food spoilage due to microbial growth.3 Bacteria adhere to and mature on food surfaces by forming biofilms, leading to contamination. Nanoparticles such as silver and zinc oxide in food coatings inhibit bacterial growth and biofilm formation.1

Furthermore, nanomaterials-based food packaging exhibits high durability, flexibility, and mechanical robustness.2 Such superior packaging allows long-term storage of food items.1 While acting as a barrier against contaminants, nanocoatings also prevent cross-contamination of food.3

Although nanotechnology is generally considered costly, nanocoatings are prepared from ultrafine materials, which consume significantly fewer resources than conventional food additives. Thus, using nanocoatings also helps to decrease the intake of food additives.3

Moreover, nanocoating-based food packaging with embedded nano-sensors can inform consumers about overall conditions and nutritional status.1

Applications in the Food Industry

Food packaging is designed to safeguard food from harmful contaminants while preventing structural, chemical, and nutritional degradation during storage or transit. It also protects food products from environmental factors like shocks, dust, odor, and microbes.

However, conventional packaging materials exhibit poor barrier properties against gas, moisture, and ultraviolet (UV) light, resulting in rapid food deterioration and shelf-life reduction.2

These shortcomings of traditional food packaging can be overcome using nanocoatings. Nanomaterials-comprising food packaging retains food quality by inhibiting microbial activity and exhibits high mechanical strength and gas barrier properties.2

For example, films constituting pullulan, carboxylated cellulose nanocrystals, and tea polyphenols are proposed for food packaging. They exhibit enhanced water barrier, thermal stability, tensile strength, UV barrier, antioxidant activity, and antimicrobial properties.1

Nanocoatings-based packaging ensures freshness, antimicrobial protection, and moisture regulation during fruit and vegetable transportation and storage. Additionally, coating foods with nano-surfaces resists the colonization of microbes on the surface with high roughness and super-hydrophobicity.2

Plastic and polythene packaging, generally used for food storage, release toxins harmful to consumers on heating with the food. Alternatively, mechanically stable nanocoatings enable hygienic storage of food and beverages.3 In addition, food storage bins are being coated with antimicrobial materials like nano-silver.2

In processing units, food materials come in contact with several surfaces during manufacturing, processing, packaging, storage, and transportation. These food contact surfaces (FCSs) require regular cleaning and disinfection to comply with regulatory standards. Applying nanocoatings on FCSs enhances their durability and prevents fouling formation and pathogenic proliferation.2

Challenges and Concerns

Despite several advantages in ensuring food safety, nanocoatings’ adoption in the industry is limited. This is mainly due to the nanoparticles’ small size and high surface reactivity. They can enter the human body through ingestion, inhalation, or skin contact and easily penetrate biological systems, causing circulatory, cardiovascular, and pulmonary diseases.1,2

Additionally, the absorption of nanoparticles in the bloodstream can initiate oxidative stress, genetic damage, and inflammation.2 Nanomaterials such as silver nanoparticles derived from food packaging have been observed to bioaccumulate in both food and humans. However, limited data is available on the dispersion of nanoparticles from nanocoatings into food and their critical toxicological effects.1

The inherent risk to human health due to nanocoatings cannot be neglected. Thus, effective regulations, policies, and laws are important for the safer use of nanocoatings in the food sector. However, only a few nations have adopted proper regulations for nanocoatings manufacturing and their application in the food industry.1

Practical limitations also exist in developing nanocoatings to regulate the surface properties and application in food systems. For example, coating fruits is time-consuming, necessitating the development of rapid and novel coating methods.1

Additionally, conventional nanomaterial synthesis processes employ chemicals, high thermal load, and radiation, which harm the environment and human health and generate hazardous intermediates.2

Apart from the technological concerns, the negative public perception regarding the impact of nanomaterials on human health and the environment hinders the wide adoption of nanocoatings in the food industry.1

Future Outlook

Significant efforts are being made to address the current challenges in nanocoating technologies, especially sustainable and safe nanomaterial synthesis. For instance, a recent study in the Journal of Polymers and the Environment proposed a biogenic method to produce edible nanocoating from guava-derived copper and zinc oxide.

The nanoparticles intercalated from guava extract were used to prepare a nanocoating on fresh papaya by dip-coating. The experimental observations for 18 days exhibited an enhanced shelf life of edible-nanocoated papaya.4

Nanocoatings hold the potential to positively impact the complete food chain, ensuring sustainable agriculture and food security, as demonstrated in a recent study in the Journal of the Science of Food and Agriculture.

They are promising delivery systems for agrochemicals such as pesticides, fertilizers, and growth regulators. Nanocoated agrochemicals exhibit targeted distribution, high efficacy, and low environmental impact. Thus, safely utilizing nanomaterials in agriculture can boost productivity while ensuring food quality and safety.5

Smart food packaging (SFP) is another innovative emerging food packaging technology. It enables constant monitoring of the packed food quality using nanocoatings capable of detecting pathogens and indicating temperature, O2 and CO2, moisture, toxins, and more.1,2

Overall, adequate legislation and guidance backed by systematic studies will accelerate the adoption of nanocoatings in the food industry. They can revolutionize food safety while ensuring enhanced food processability, shelf life, taste, and quality.3 This, in turn, will positively impact global food safety and public health in the long term.

More from AZoNano: What Role Does Boron Nitride Play in 3D Printing?

References and Further Reading

1. Ansari, MA. (2023). Nanotechnology in Food and Plant Science: Challenges and Future Prospects. Plants. DOI: 10.3390/plants12132565

2. Jegatheesan, V., Bandara, N., Sarkar, P., Sarkar, A., Pal, K. (2022). Food, Medical, and Environmental Applications of Nanomaterials. Elsevier. ISBN: 978-0-12-822858-6. https://shop.elsevier.com/books/food-medical-and-environmental-applications-of-nanomaterials/jegatheesan/978-0-12-822858-6#full-description

3. Hussain, CM. (2022). Handbook of Microbial Nanotechnology. Academic Press, Elsevier. ISBN: 978-0-12-823426-6. https://shop.elsevier.com/books/handbook-of-microbial-nanotechnology/mustansar-hussain/978-0-12-823426-6

4. Sharma, B., Nigam, S., Verma, A., Garg, M., Mittal, A. P., Sadhu, SD. (2023). A Biogenic Approach to Develop Guava Derived Edible Copper and Zinc Oxide Nanocoating to Extend Shelf Life and Efficiency for Food Preservation. Journal of Polymers and the Environment. DOI: 10.1007/s10924-023-02972-1

5. Shukla, K., Mishra, V., Singh, J., Varshney, V., Verma, R., Shrivastava, S. (2024). Nanotechnology in Sustainable Agriculture: A Double‐Edged Sword. Journal of the Science of Food and Agriculture. DOI: 10.1002/jsfa.1334