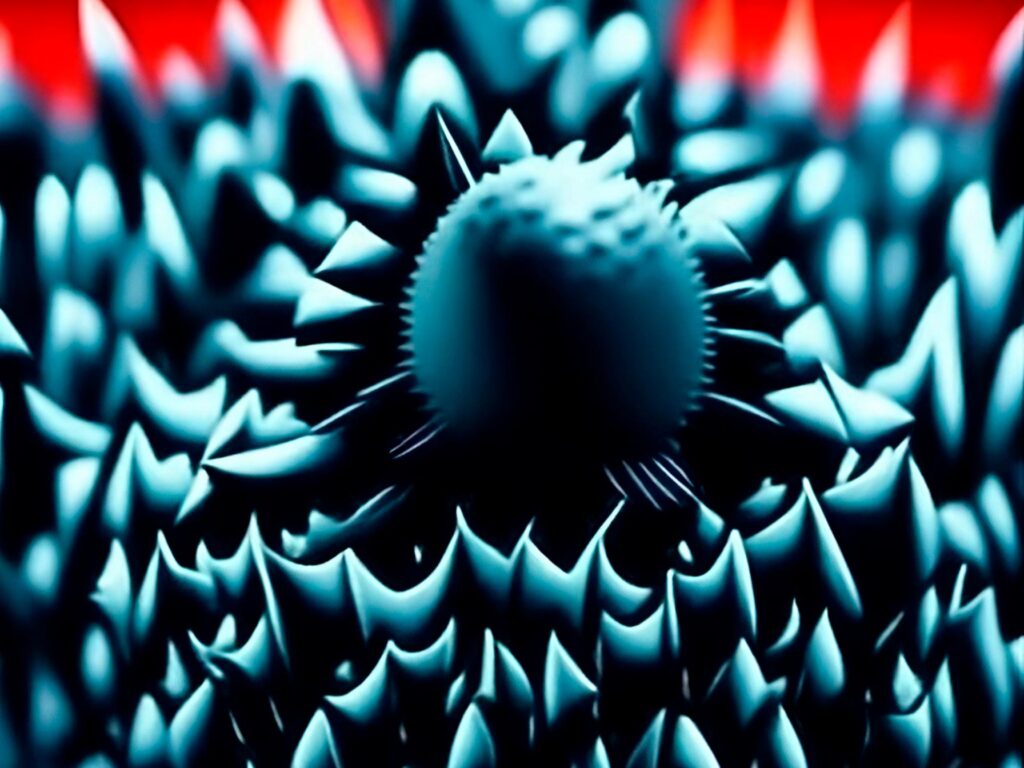

Innovative silicon spikes developed by URV and RMIT University effectively neutralize 96% of viruses, promising safer laboratory and healthcare settings. The image shows a virus on a nanostructured surface. Credit: ACS Nano

An international research project in which the URV has taken part has designed and manufactured a surface that has virucidal properties but does not use any chemicals.

A team of researchers from the URV and RMIT University (Australia) has designed and manufactured a surface that uses mechanical means to mitigate the infectious potential of viruses. Made of silicon, the artificial surface consists of a series of tiny spikes that damage the structure of viruses when they come into contact with it.

The research has revealed how these processes work and that they are 96% effective. Using this technology in environments in which there is potentially dangerous biological material would make laboratories easier to control and safer for the professionals who work there.

The Process of Creating Virucidal Surfaces

Spike the viruses to kill them. This seemingly unsophisticated concept requires considerable technical expertise and has one great advantage: a high virucidal potential that does not require the use of chemicals.

The process of making the virucidal surfaces starts with a smooth metal plate, which is bombarded with ions to strategically remove material. The result is a surface full of needles that are 2 nanometers thick – 30,000 would fit in a hair – and 290 high.

“In this case, we used silicon because it is less complicated technically speaking than other metals,” explains Vladimir Baulin, researcher from the URV’s Physical and Inorganic Chemistry Department.

Inspiration from Nature and Specific Virus Studies

This procedure is not new for Baulin, who has spent the last ten years studying mechanical methods for controlling pathogenic microorganisms inspired by the world of nature: “The wings of insects such as dragonflies or cicadas have a nanometric structure that can pierce bacteria and fungi,” he explains.

In this case, however, viruses are an order of magnitude smaller than bacteria so the needles must be correspondingly smaller if they are to have any effect on them. One example of this is hPIV-3, the object of study of this research, which causes respiratory infections such as bronchiolitis, bronchitis, or pneumonia. The so-called parainfluenza viruses cause a third of all acute respiratory infections and are associated with lower respiratory tract infections in children.

“In addition to being an epidemiologically important virus, it is a model virus, safe to handle, as it does not cause potentially fatal diseases in adults,” says Baulin.

Research Methodology and Effectiveness

The process by which viruses lose their infectious ability when they come into contact with the nanostructured surface was analyzed in theoretical and practical terms by the research team. The URV researchers, Vladimir Baulin and Vassil Tzanov, used the finite element method – a computational method that divides up the surface of the virus and processes each fragment independently – to simulate the interactions between the viruses and the needles and their consequences. At the same time, the RMIT University researchers carried out a practical experimental analysis, exposing the virus to the nanostructured surface and observing the results.

Potential Applications and Safety Enhancement

The findings show that this method is extremely effective and incapacitates 96% of viruses that come into contact with the surface within a period of six hours. The study has confirmed that the surfaces have a virucidal effect because of the ability of the needles to destroy or incapacitate viruses by damaging their external structure or piercing the membrane.

Using this technology in risk environments such as laboratories or health centers in which there is potentially dangerous biological material would make it easier to contain infectious diseases and make these environments safer for researchers, health workers, and patients.

Reference: “Piercing of the Human Parainfluenza Virus by Nanostructured Surfaces” by Samson W. L. Mah, Denver P. Linklater, Vassil Tzanov, Phuc H. Le, Chaitali Dekiwadia, Edwin Mayes, Ranya Simons, Daniel J. Eyckens, Graeme Moad, Soichiro Saita, Saulius Joudkazis, David A. Jans, Vladimir A. Baulin, Natalie A. Borg and Elena P. Ivanova, 21 December 2023, ACS Nano.

DOI: 10.1021/acsnano.3c07099