Dr. Jaeyeon Pyo’s team at the Korea Electrotechnology Research Institute (KERI) has become the first in the world to reveal light emission patterns from 3D-printed nanowires, which has been published as a cover article in the journal ACS Nano.

The higher resolution in display devices signifies the more pixels in a given screen size. As pixel density increases, movies and images are displayed with greater precision and detail. In this regard, ongoing research aims to fabricate smaller light-emitting devices, from the micrometer scale (one millionth of a meter) to the nanometer scale (one billionth of a meter).

As the size of light-emitting devices shrinks to hundreds of nanometers, peculiar changes occur in the light-matter interaction, resulting in significantly different emission patterns compared to macro structures. Therefore, understanding of light emission from nanostructures is an essential prerequisite for the practical application of nanoscale light-emitting devices.

The KERI’s research team, dedicated to display research using nanophotonic 3D printing technology for years, revealed highly directional light emission patterns from the 3D-printed nanowires for the first time in the world.

Typically, it is challenging to uniformly fabricate light-emitting materials of desired sizes at specific locations using conventional chemical or physical vapor deposition methods. However, KERI’s 3D printing technology allows precise control of the diameter through the restriction of the printing nozzle’s aperture, enabling the reliable fabrication of light-emitting materials at desired locations with a wide range of sizes (diameter from 1/10,000th of a meter to 1/10th millionth of a meter).

Dr. Jaeyeon Pyo’s team experimentally observed and measured light emission patterns from specimens precisely fabricated using the nanophotonic 3D printing technology, ranging in size from the nanometer- to micrometer-scale. The team also conducted electromagnetic wave simulations for in-depth analysis and cross-validation of their arguments.

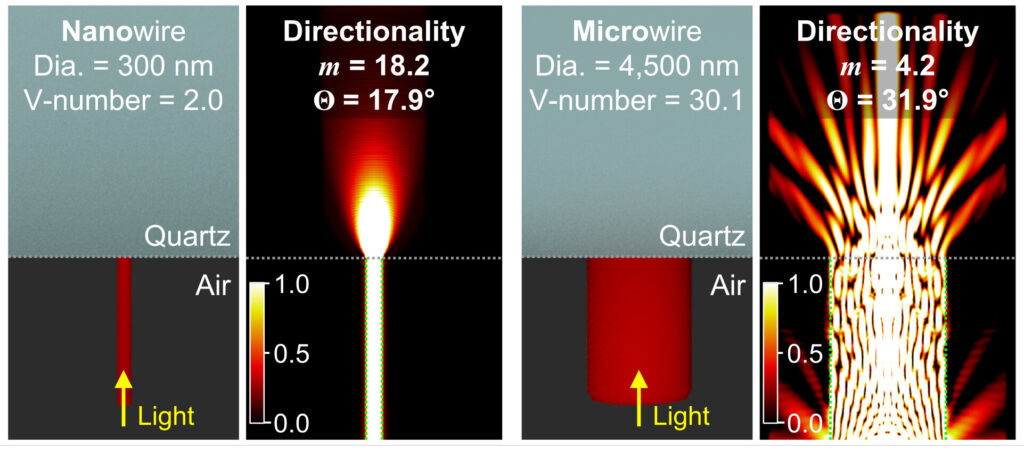

As a result, when the size of light-emitting materials becomes as small as 300 nanometers in diameter, internal reflection of light vanishes due to spatial confinement, leading to one-directional straight propagation of light. Consequently, the light emission pattern becomes highly directional.

Typically, light propagates through diverse paths within a given internal structure, resulting in broad emission patterns as their superposition. However, in nanowire structures, only a single path exists, leading to the observed highly directional emission pattern.

The observed highly directional attribute can significantly enhance the performance of displays, optical storage media, encryption devices, and more. Macro-structures with broad emission patterns can suffer from optical crosstalk when densely integrated, causing signals to overlap or blur.

In contrast, nanowires with highly directional emission patterns allow clear separation between signals from each structure at high densities, eliminating distortions in representation or interpretation. The highly directional emission of nanowires makes them suitable for high-performance devices, as experimentally demonstrated by KERI’s team.

Dr. Pyo stated, “Research on optical physics at the nanoscale is challenging, especially due to the difficulty in specimen preparation, which is often high-cost and time-consuming. Our contribution demonstrates that the 3D printing method can be a versatile platform for studying optical physics owing to its simple, flexible, and low-cost characteristics.”

He added, “This research will significantly contribute to the cutting-edge display technologies, and quantum physics, which are part of South Korea’s ‘National Strategic Technology Nurture Plan.”

The research team anticipates that their contribution will attract significant interest in the fields of virtual reality (AR, VR), beam projectors, optical storage media, photonic integrated circuits, encryption technologies, and security printing, where ultra-small light-emitting materials can be utilized. They aim to continue investigating various optical phenomena occurring at the nanoscale using the 3D printing method, leveraging its capability for free-form fabrication.