The same material from which you drink your morning coffee could transform the way scientists detect disease, purify water, and insulate space shuttles thanks to an entirely new approach to ceramic manufacturing.

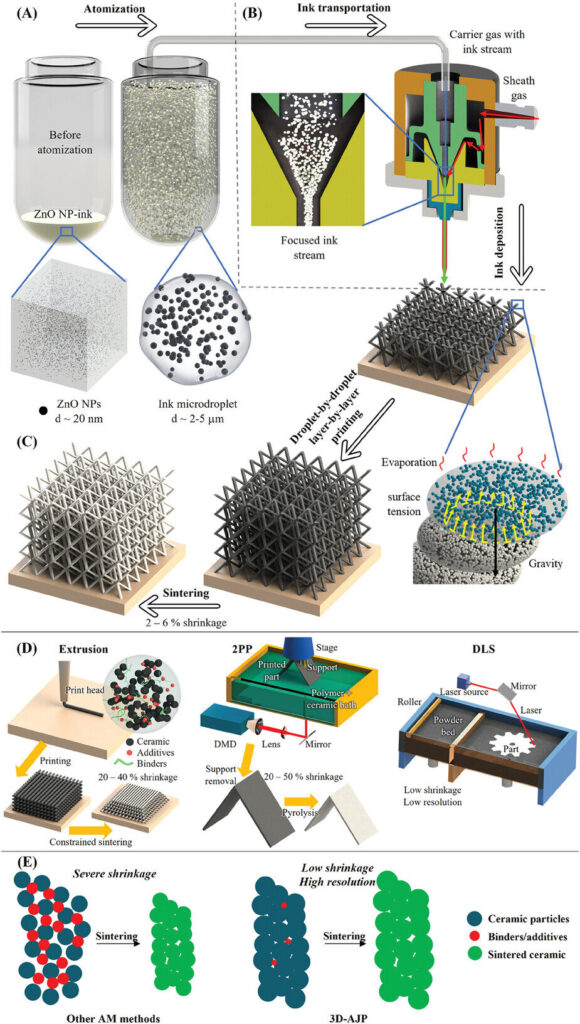

Published in Advanced Science, 3D-AJP is an aerosol jet 3D nanoprinting technique that allows for the fabrication of highly complex ceramic structures that—at just 10 micrometers (a fraction of the width of human hair)—are barely visible to the naked eye. These 3D structures are made up of microscale features including pillars, spirals, and lattices that allow for controlled porosity, ultimately enabling advances in ceramic applications.

“It would be impossible to machine ceramic structures as small and as precise as these using traditional manufacturing methods,” explained Rahul Panat, professor of mechanical engineering at Carnegie Mellon University and the lead author of the study. “They would shatter.”

Ceramics are believed to be the key to emerging engineering systems because of their wear resistance, thermal stability, thermal insulation, high stiffness and biocompatibility. While existing 3D printing techniques have opened doors for ceramics fabrication, oftentimes severe shrinkage and/or defects are observed during post-printing processing due to the removal of additives from the ink that were needed to support the material during printing. With shrinkage ranging from 15–43%, it is challenging for fabricators to set printing parameters that would output the ideal part.

3D-AJP does not rely on additives in the ink and therefore sees only a 2–6% shrinkage rate, so manufacturers can feel confident that the structure they want is the structure they’ll print.To ensure this, the research team performed a detailed manufacturability study to identify the CAD programs needed to produce the final shape.

Additionally, the team, including postdoc Dr. Chunshan Hu, demonstrated 3D-AJP’s unique ability to print two ceramic materials in one single structure, which allows for advanced applications.

“Using these structures, we can detect breast cancer markers, sepsis and other biomolecules from a blood sample in just 20 seconds,” said Panat.

This application, which is an extension of past research in which Panat’s group developed a metal biosensor to detect COVID-19 in just ten seconds, is advantageous, because compared to metal, ceramic sensors can be manufactured nearly five times faster.

Panat also cites the benefits of this technology in water purification and thermal insulation.

“In the presence of UV light and zinc oxide, chemicals can be degraded, so by creating a 3D structure with a higher surface area we can increase the speed and the effectiveness of water purification by four times,” he said. “Additionally, our ability to control the porosity of these structures, allows us to control and tailor thermal conductivity of structures such as the insulators used in space shuttles.”